Groove Jones recently helped launch a new VR (Virtual Reality) training tool for Henkel Loctite as part of a Vehicle Repair Training and Application Center. The facility offers hands-on technical application training for automotive aftermarket products and collision repair products and provides mechanics, collision repair, and glass installer technicians with the tools and knowledge to make automotive repairs faster, safer, and more reliable.

The VR experience is a tool that allows both employees and their customers to work through a variety of use-case scenarios. The experience then grades the user on how they performed, providing instant feedback for additional training and insight from a company expert.

VR Training Module

The VR experience tests the user on their knowledge of the unique products to accomplish the following aftermarket automobile repairs. Virtual Reality (VR) is an exceptional tool for training, offering immersive, hands-on experiences in a safe and controlled environment. By simulating real-world scenarios, VR allows users to practice skills, make decisions, and face challenges without the risks or costs associated with traditional training methods. It’s particularly effective for industries like healthcare, manufacturing, or corporate onboarding, where experiential learning is essential. Furthermore, its interactive nature enhances knowledge retention and engagement, ensuring trainees are better prepared for real-world applications.

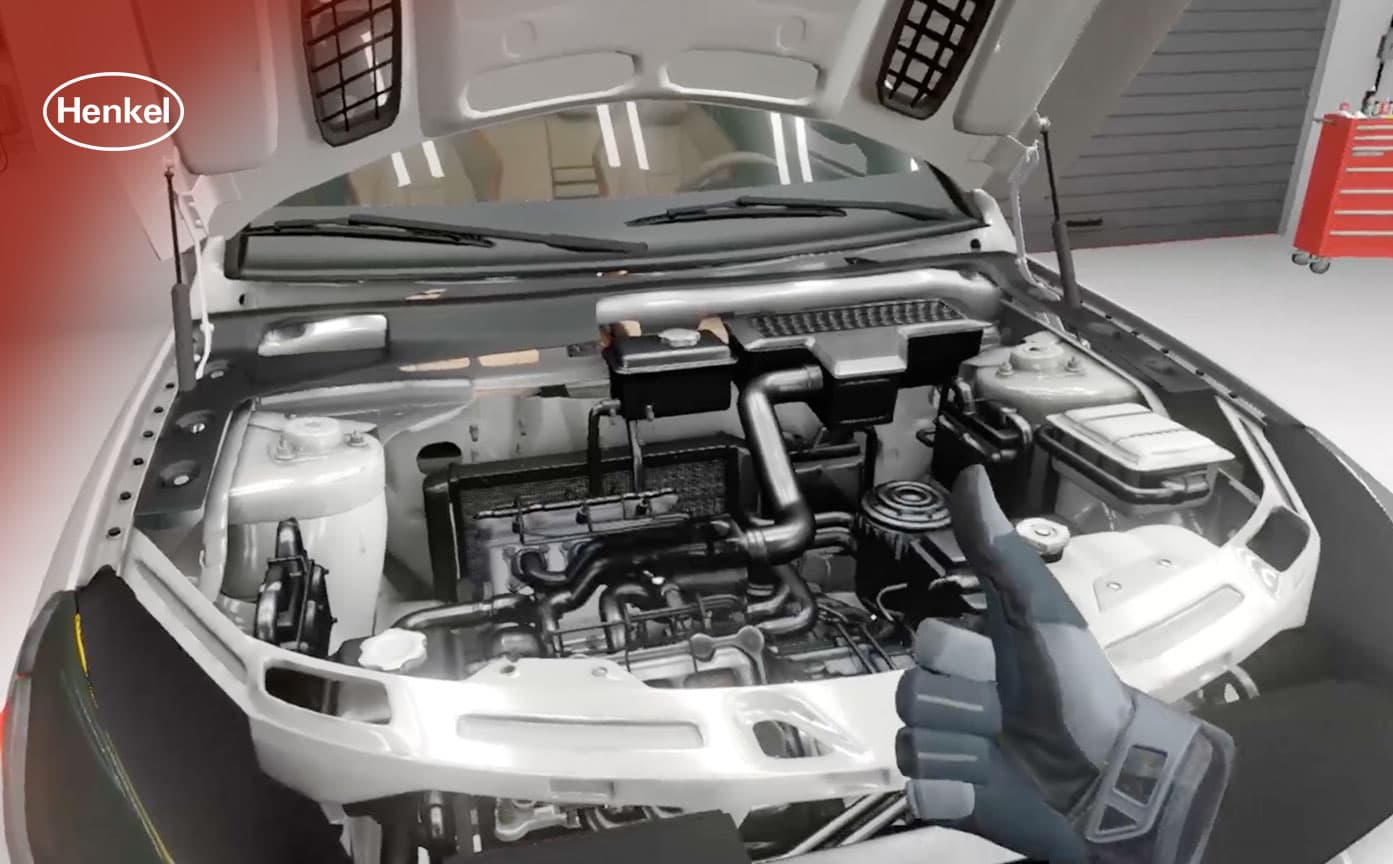

The experience always begins with instructing the user to put on their safety gear, which includes gloves and goggles, before they can begin working on the cars.

The user is then tested on their knowledge of Loctite products to fix a variety of issues that they may face in real life. The experience starts with simple issues and then ramps up in difficulty with issues that take multiple steps to complete.

Below is an overview of the various interactions and modules developed for the training SIM.

- Cylinder Sleeve – A connecting rod broke, causing the piston to score the cylinder wall. The user will bore out the cylinder to accommodate a sleeve of proper dimensions. Once complete, the user must apply the correct product on the sleeve to accommodate the gap and heat requirements of the engine.

- Adjust Rocker Arm – Vehicle operators have heard tapping from the rocker’s arms. The user must retrieve and use the proper product to prevent them from loosening in the future.

- Fix and Reattach Loose Body Trim – There is a piece of the bumper lip that has cracked. It is made out of carbon fiber, so the user must repair the damage using a product to fill in the gap and then reattach it to the vehicle.

- Fix Oil Leak Around Oil Pan – There is an oil leak coming from the pan. The user must drop the pan, clean away the remaining gasket, and apply to the circumference.

- Fix Leaking Brake Lines Due to Corrosion and Replace with New Brake Line – A repair is needed as a result of a leaking brake line due to corrosion. This must be replaced. The user must find and apply the correct product and adequately seal all fittings on the new brake line to prevent future leaks.

- Replace Muffler – The bolts on the exhaust coupling have rusted and cannot be removed by standard measures. Before the repair can be completed, the user must use Freeze and Release to loosen the bolts for removal. Since the previous installation of the bolts failed to use a lubricant to protect the assembly from rusting, the user must use the proper product to prevent this in the future before reattaching.

Products Used in the Experience

- General-purpose thread locker of medium bond strength. This thread locker secures and seals bolts, nuts, and studs to prevent loosening due to vibration. The product works on all metals, including passive substrates such as stainless steel, aluminum, and plated surfaces.

- A dual cure, acrylic methacrylate ester fluorescent thread locker is designed for the permanent locking and sealing of threaded fasteners.

- Flexible, gasketing material for use on rigid machined flanges

- High strength and high temperature resistant retaining compound.

- A very high-strength fast cure retaining compound is a high-strength, high-viscosity room temperature curing adhesive used to join fitted cylindrical parts.

- Cyanoacrylate adhesive is compatible with leather, paper, plastic, rubber, and wood material.

- The hybrid ultra-fast adhesive is a two-component versatile instant adhesive that bonds together plastics, rubbers, and metals.

- Silicone sealant and cures on exposure to moisture in the air to form a tough rubber gasket.

- Anti-Seize Lubricant is a heavy-duty, temperature-

resistant, petroleum-based compound fortified with graphite and metallic flake.

About the Facility

The 2100 sq. ft customer facility is one of Henkel’s 11 Vehicle Repair Training & Application Centers around the world, that brings together best-in-class technical training with cutting-edge technology in a collaborative environment. Below are some photos from the opening of the facility in Rocky Hill CT.

Below are some screenshots from inside the VR version of the training facility.