Svante offers companies in emissions-intensive industries a commercially viable way to capture large-scale CO₂ emissions from existing infrastructure, either for safe storage or recycling for further industrial use in a closed loop. They can capture CO₂ directly from industrial facilities such as cement plants, steel mills, oil refineries, and pulp and paper mills. Carbon Capture and Storage is a way of reducing carbon emissions, which could be key to helping to tackle global warming.

Svante recently hired Groove Jones to create an interactive VR experience highlighting how their technology is used to capture CO2 from industrial flue gas.

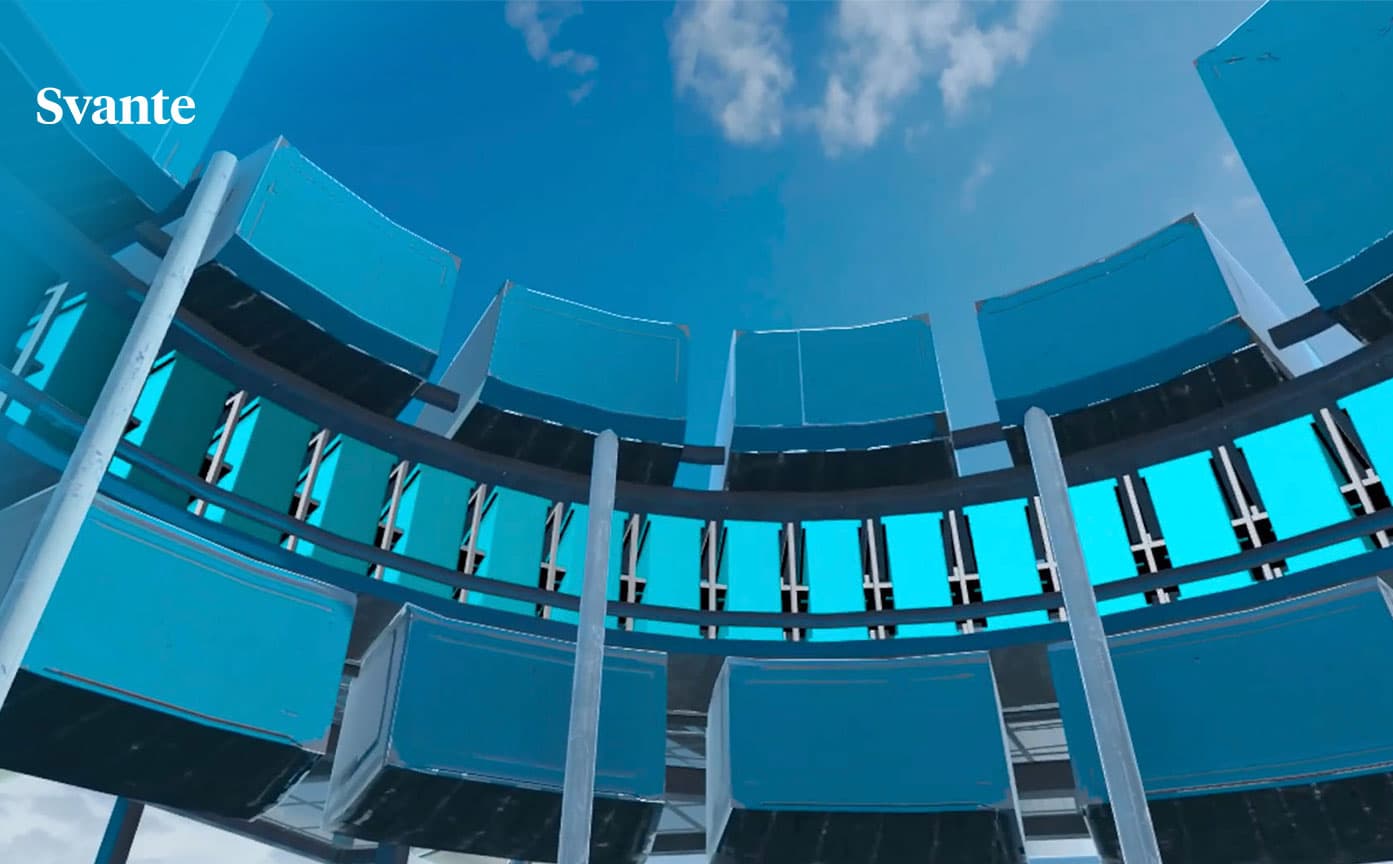

Svante’s industrial point source carbon capture technology consists of a patented architecture of structured adsorbent beds (filters coated in solid nanomaterials), a proprietary capture process cycle design, and an industrial contactor machine to capture, concentrate, and release pure CO2.

Their technology captures diluted carbon dioxide from industrial flue gas, concentrates it, and then releases it for safe transportation and deep underground storage or further industrial use, all in 60 seconds.

The VR experience allows customers to enter an industrial facility virtually and see the technology up close. It also allows Svante customers to see the entire process from a bird’ s-eye view, helping them tell their stories uniquely and compellingly.

Taking the Virtual Carbon Capture Plant Tour

The VR experience transports the user into a fictional 3d industrial environment based on a steam methane reforming facility that makes hydrogen. Here, the Svante carbon capture plant is in place, virtually capturing 1 million tonnes of CO2 annually. This begins with a birdseye view of the facility.

The user can move between multiple hotspots to see the Svante technology from different angles and learn about its features.

By activating individual hot spots along the tour, the user can see information and 3D models of key points.

Users can also transport themselves to the ground level and move through the facility for an up-close look.

Here, we see how flue gas is being diverted into the Svante capture plant, where the carbon dioxide is trapped and purified to be safely transported.

The direct contact cooler treats the flue gas by cooling it down and reducing contaminants.

The flue gas is then sent to the Svante RAM (Rotary Absorption Machine/industrial contactor machine).

The VR experience allows the user to step into the machine’s center.

Users can move up to the operator’s position, where they get an up-close look at how maintenance staff can access local instruments, the filter installation platform, drive motors, and seals.

Leveraging VR at Trade Shows and Product Demonstrations

While not all customers can travel to see Svante’s capture plants in person, they can easily try on a VR headset and be virtually transported to one. The Svante team is now using the VR Carbon Capture Plant Tour as a sales tool to increase customer engagement and education, enabling them to show more customers how their technology works in person at tradeshows and on Teams calls.

To learn more about Svante, visit – https://www.svanteinc.com/