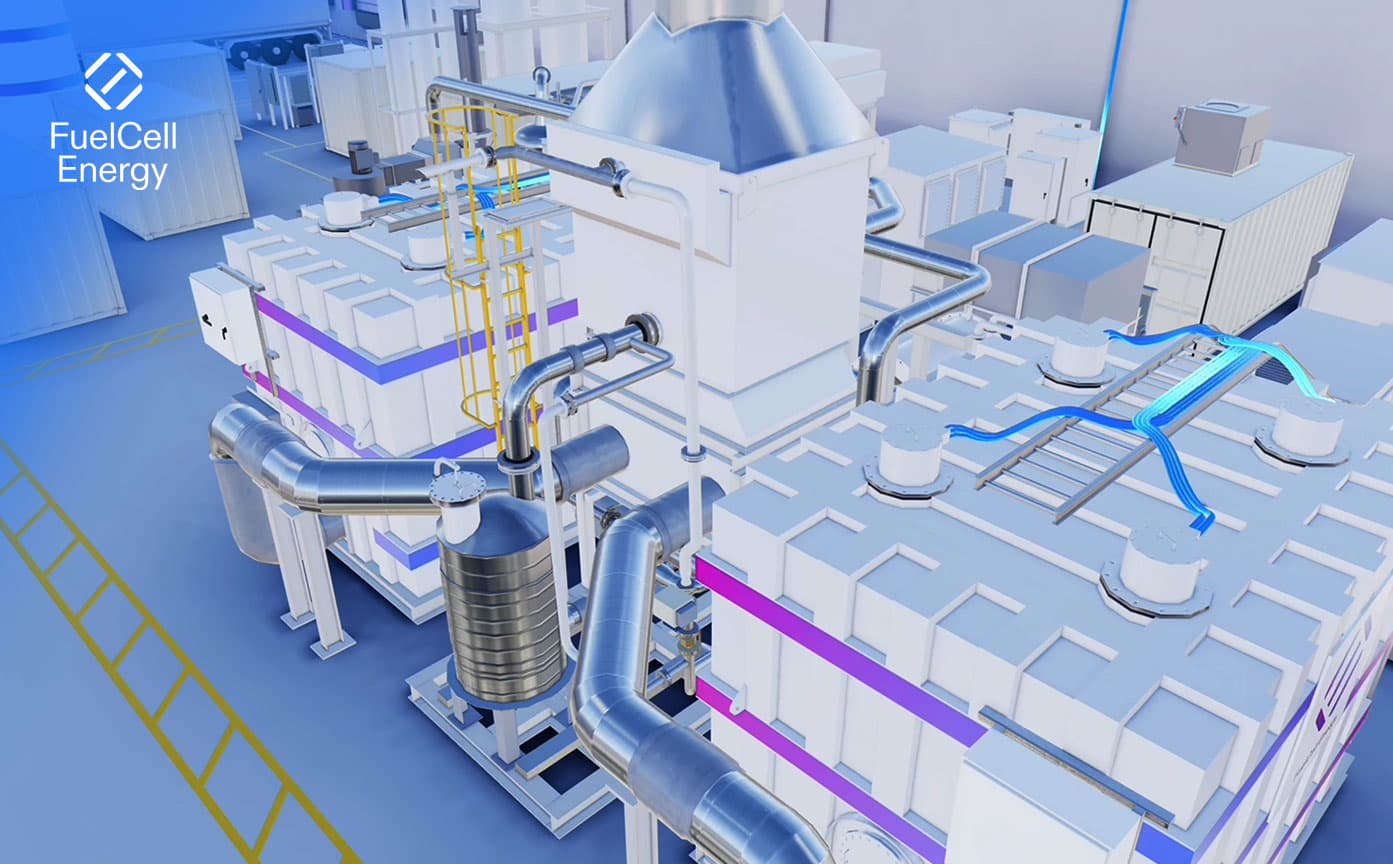

Using WebGL for CO2 Recovery Walkthrough

Groove Jones worked with FuelCell Energy to design and develop a WebGL interactive experience showing how carbonate fuel cells can produce electricity while recycling CO₂. Self-supplying CO₂ ensures consistent pricing, availability, and quality of a key ingredient.

Purification modules can ensure the product meets the required quality standards, from industrial-grade to ISBT Beverage-grade CO₂.

Check out the site – https://go.fuelcellenergy.com/carbon-recovery-walkthrough

The CO2 Recovery Walkthrough

The experience showcases the fictional bottling company – Groove Soda.

CO₂ Recovery

Carbonate fuel cells can produce electricity while recycling CO₂. Self-supplying CO₂ ensures consistent pricing, availability, and quality of a key ingredient. When paired in a system with purification modules, the CO₂ can be purified to beverage grade.

Fuel Flexible

Carbonate fuel cells can run off various methane-based (CH4) fuels like natural gas, biogas, or anaerobic digester gas. Creative breweries have fueled their power plants with renewable waste byproducts from their brewing processes.

Fewer Emissions

Fuel cells electrochemically react to fuel and air to create power. The reaction is virtually free of pollutants since there is no combustion. Methane (CH4) is steam-reformed into hydrogen (H2) and carbon dioxide (CO₂). The cell reactions concentrate the CO₂, resulting in a purified stream available for recovery.

Heat

Fuel cells produce heat as a useful byproduct. Combined heat and power (CHP) systems can recover heat that can be used instead of burning fuel in on-site thermal systems. Fuel cell systems can be configured to provide steam or hot water to reduce on-site boiler operation, which can result in additional savings and emission reductions.

Power Production

Electricity can be delivered to the grid or used by the facility. Fuel cells can be configured as microgrids, supplying power during normal operation and in the event of a disturbance. On-site power can maximize production uptime by helping to avoid costly outages.

Water Circularity

The output stream is cooled and pre-filtered before CO₂ is extracted, leaving water and hydrogen, which can be reused by the system to reduce consumption. In some applications, fuel cells can generate more clean water than they consume.

Quality Control

Purification modules can ensure the product meets the required quality standards, from industrial-grade to ISBT Beverage-grade CO2 standards. Purifying CO₂ on-site lets producers continuously monitor, document, and control the quality, flavor, and supply of their source. Self-supplying CO₂can reduce the risk of third-party quality issues, supplier source contamination, lack of availability, and force majeure price increases.

Beverage-Grade Co2

CO2 captured from the fuel cell system is already clean because of the lack of combustion products and can be easily purified to ISBT Beverage-grade CO₂ standards. CO₂ recovered from fuel cells can also be sold, sequestered, or used directly on-site for many other industrial purposes.

Once the users go through the experience and learn about CO₂ recovery, they will be driven to a Carbon Savings Calculator where they can calculate their personalized savings estimate.

Afterward, users can sign up to learn more and see how FuelCell Energy can help them on their journey to net zero.

Check out the site – https://go.fuelcellenergy.com/carbon-recovery-walkthrough

FuelCell Energy Experience at World Brewing Congress

FuelCell Energy recently used the interactive experience at the World Brewing Congress in Minneapolis, Minn. The event provided a platform for FuelCell Energy to showcase its innovative solutions for CO2 utilization and sustainability in the brewing, food, and agriculture industries.

Countries and companies around the world are rushing to reduce their carbon footprints, particularly with respect to the energy, transportation, and heavy industry sectors. However, there is a demand for a cleaner way of generating CO2. The certainty of supply and long-term pricing for CO2, especially in the food and beverage industry, is mission critical because CO2 provides the bubbles in beer, keeps steak fresh, helps process the sugar in dessert, and pH balances the water we drink. In fact, CO2 permeates the food chain and is a glue between manufacturers, processors, stores, restaurants, and the consumer.

About FuelCell Energy

FuelCell Energy’s platforms help organizations transform their energy strategy while staying true to their net-zero commitments. FuelCell Energy is helping deliver a more sustainable future by decarbonizing power and producing hydrogen worldwide. Their platforms can help businesses and communities with power generation, carbon capture, hydrogen production, and energy storage.

Award Winning Production

2024 Horizon Interactive Awards – GOLD

Category: Websites – Corporate & B2B