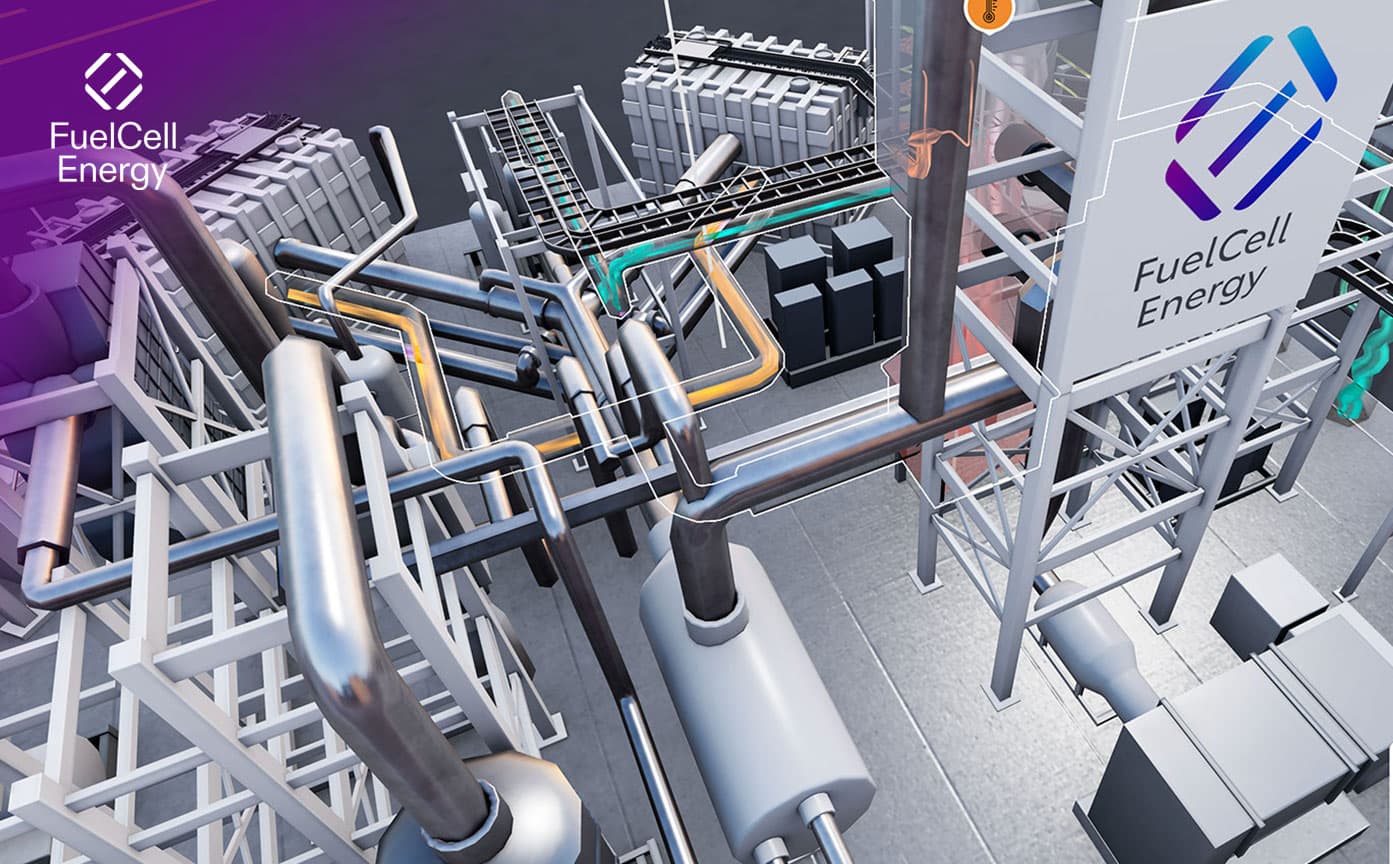

Groove Jones worked with FuelCell Energy to design and develop a WebGL, interactive experience telling the FuelCell Energy story and to highlight their work at the Toyota Long Beach Port facility – an epic way of being transported to the Port of Long Beach to learn and discover without leaving your own home!

The Toyota Logistic Services Distribution Center is an innovative 166,500-square-foot facility that is dedicated to processing over 200,000 auto imports annually at the Port of Long Beach. Targeted to achieve LEED certification, it incorporates Carbon Neutral, Tri-Generation, Fuel Cell, and Hydrogen strategies. Talk about eco-friendly, as this is the first commercial-scale tri-generation project underway!

FuelCell Energy’s tri-generation system installed at Toyota’s Port of Long Beach site will use directed renewable biogas to deliver hydrogen, electricity, and water. The carbon-neutral 2.3 MW fuel cell system will power the site, supply hydrogen to fuel vehicles, reduce the port’s emissions, and generate water to wash cars.

When users enter the experience, they are transported to the Toyota Facility, where they can be transported to the FuelCell Energy location. Once there, a prompt starts the experience to learn more about how FuelCell Energy’s tri-generation system will use directed renewable biogas to deliver hydrogen, electricity, and water to Toyota’s Port of Long Beach site.

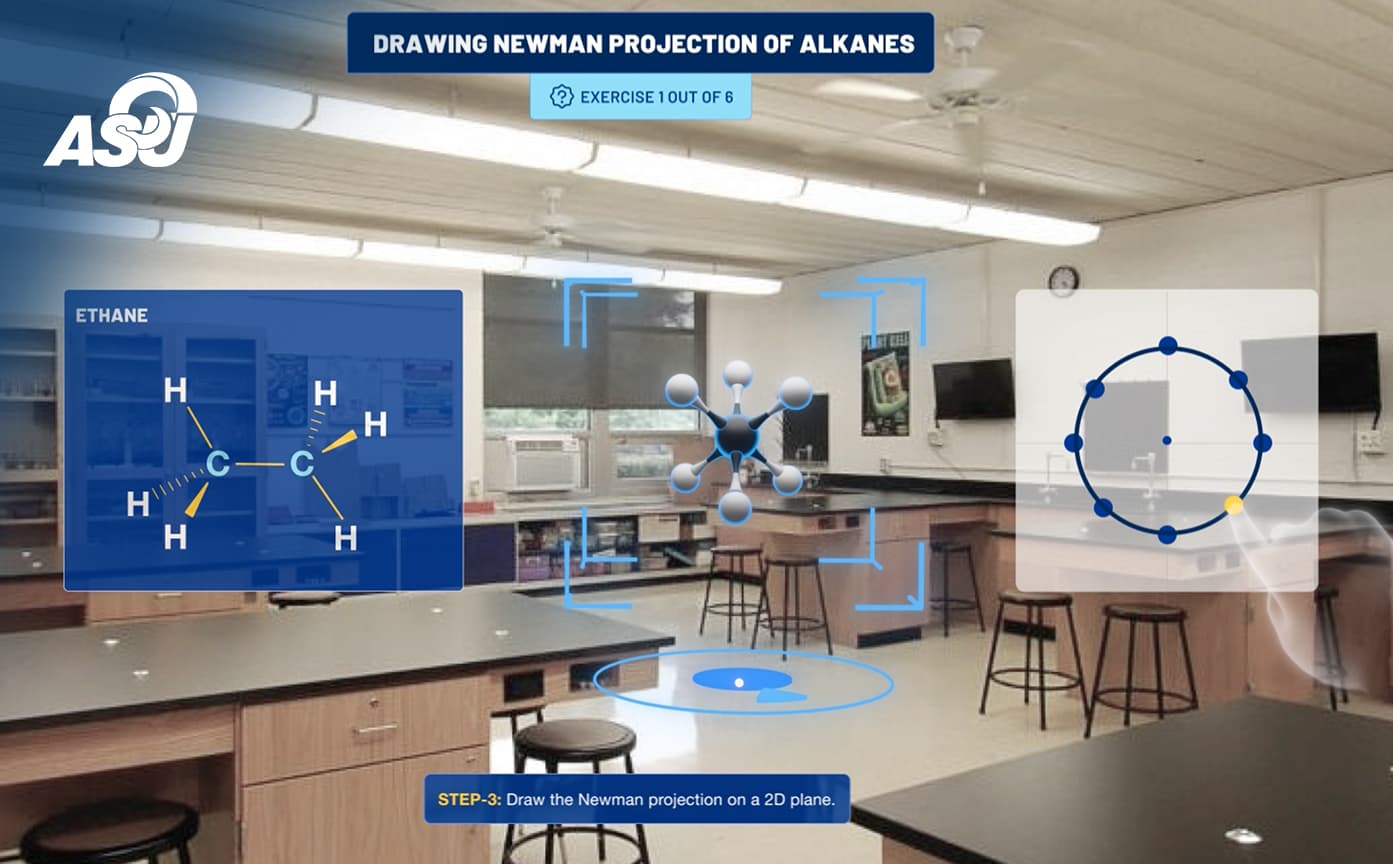

Mobile and Desktop Friendly

Visitors can interact with the site through their computer or mobile device. The site is responsive and provides a seamless experience regardless of the device you are using.

Key Highlights of the Process

Users will flow through highlights of the plant, where they will learn about the following:

Biogas: Renewable Biogas from organic waste is delivered to the site by pipeline. The biogas contains methane that is converted into hydrogen inside the fuel cell stacks.

Saturation: Biogas is sprayed with water and humidified inside the saturator. Wetting the gas to an ideal water/methane ratio allows the steam-reforming conversion of the fuel to hydrogen in the fuel cell stacks.

Heated: 1000°F exhaust from the fuel cell stacks passes over tubes containing saturated gas, heating the wet has for the steam reforming process.

Fuel Cell Stacks: The fuel cell stacks steam-reform the wet gas into hydrogen using heat and water as byproducts of the fuel cell electrochemical power generation process. The combustion-free process emits water, not pollutants.

Electricity: Direct current from the fuel cell is converted into alternating current at the right voltage and frequency for delivery to the power grid or on-site use at nearby facilities.

Water: Fuel gas leaving the fuel cell contains excess hydrogen and water vapor. Cold air is blown over tubes containing the gas, cooling the gas, so the vapor condenses as water and is removed from the gas. Water is reused by the fuel cell, and the excess is sent to Toyota’s car washing station.

Hydrogen: Hydrogen is purified to the level required by fuel-cell electric vehicles. The purified hydrogen is then delivered to the hydrogen fueling station and dispensed to fuel zero-emission vehicles.

Check out the experience at https://trigen.groove-tech.com/

Award-Winning Production

GOLD – 2025 HORIZON INTERACTIVE AWARDS

CATEGORY: WEBSITES – CORPORATE & B2B